Leading Manufacturer & Supplier of Effluent Treatment Plant in India

The Effluent Treatment Plant [ETP] plant is designed to treat the effluent coming from various areas of the plant. The treatment of different effluents varies with the type of effluent. Industrial wastewater contains a diversity of impurities and therefore for this reason alone, its treatment establishes a special task. Shubham Inc. offers comprehensive range of Effluent Treatment Plants that is highly effective.

Industries during the manufacturing process generates huge quantity of high toxic effluents which yield very high BOD, COD, TS and TDS level with collared and odour in effluent.

Based on the above mentioned fact,

SHUBHAM INC has developed a next generation

Effluent Treatment plant by which it will be possible to overcome all the environmental problems. The concept and the treatment is based on the belief that the entire biological and chemical requirement should go down and the coming out should not be polluted.

For reducing the BOD, COD, colour, nitrogen and toxic level of the effluent, SHUBHAM is offering a various solutions from ASP (Activated Sludge Process) to advance Membrane technologies as per treated water uses.

SHUBHAM has also developed and offering a ZLD (

Zero Liquid Discharge) system to recycle treated water for utility and process applications.

We provide innovative and economical systems for waste with expertise is advantageously employed for the technical and economic optimization of every subsequent facility.

SHUBHAM INC use the best-in-class technology and cutting-edge tools to foster high-quality, sustainable, community-level water supply

Sewage Treatment Plant and

Effluent Treatment Plants projects in Gujarat, India across the ahmedabad, Surat, Rajkot and Baroda.

Some processes followed by us are:

• Aerobic Biological Process

• Anaerobic Biological Process

• Chemical-physical process

TREATMENT REQUIREMENTS:

1. Oil & grease Separation

2. Neutralization of Acids and Alkali

3. Removal of Suspended Solids

4. Reduction & Removal of metallic impurities

5. Reduction of high organic content: BOD, COD, P, TKN, etc.

6. Dissolve impurities for ZLD system.

TREATMENT METHODS

• Primary clarifications

• Biological process

• Secondary clarifications.

• Tertiary treatment

• Polishing units i.e. UF, RO and DM (Optional for recycling or ZLD)

Applications:

• Textile Industries

• Distilleries

• Pharmacy Industries.

• Chemical Industries

• Paper Industries

• Tannery Industries

• Dye & Dye Intermediaries

• Edible Oil Refineries

• Electroplating Industries

Features:

• Sturdy construction

• Resistant to corrosion

• Superior performance

• Rapid installation

• Less civil work involved

• Flexible in reworking

Shubham Inc is the leading water and

waste water management company providing the most comprehensive water and wastewater treatment systems and services for

industrial, institutional and municipal customers. We are a reputed manufacturer, exporter, importer, supplier and trader of an exhaustive range of Water and Waste Water Treatment Products and Services such as

Filtration Systems, Water Softening Systems, Sewage Treatment Plant, Water Treatment Plant, WTP, Well Water Treatment, River Water Treatment Plants industrial RO Plant , etc.

Shubham inc use the best-in-class technology and cutting-edge tools to foster high-quality, sustainable, community-level water supply sewage –

Effluent treatment plant and industrial RO plant projects in Gujarat, India across the Ahmedabad, Surat, Rajkot and Baroda.

Shubham inc is a leading

manufacturer of Sewage Treatment Plants for the industrial, Government and Municipal . With a decade old experience, shubham inc has successfully executed over 1000 installations in industries, Government, hotels, and Municipal becoming a preferred supplier of Sewage Treatment Plants and

Zero Liquid Discharge Plant and Effluent Treatment Plant.

We, at Shubham, Offer a wide array of

water and wastewater treatment products and services such as filtration systems, RO Systems, water softening systems, sewage treatment plants and more.

Apart from public health and pollution norms, STP facilities has also becoming new source of water which can be used for irrigation, horticulture, industrial and many other non-potable purpose. Recycling of sewage treated water directly reduce consumption of fresh water and help to come out from water scarcity problem.

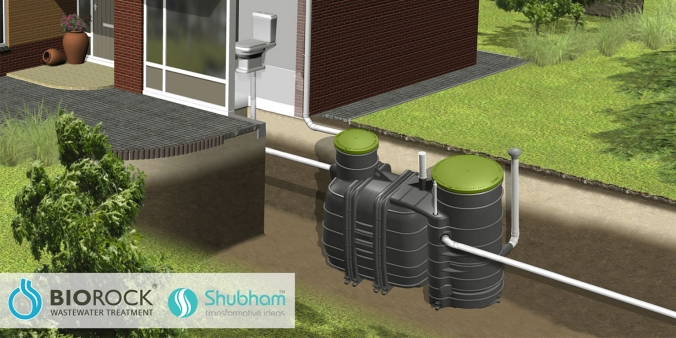

Sewage treatment is the process of removing contaminants from domestic wastewater called “Sewage” coming from various part of city and inhabitant area, which includes physical, chemical and biological processes to produce an environmentally safe fluid waste stream (or treated effluent) and a solid waste (or treated sludge) suitable for disposal or reuse (usually as farm fertilizer).

Various technologies from Oxidation pond to Activated sludge process and advance MBBR to MBR process has been adopted by municipal and government bodies to provide effective treatment of domestic sewage water depending upon the uses of treated sewage water which formulate as

Apart from public health and pollution norms, STP facilities has also becoming new source of water which can be used for irrigation, horticulture, industrial and many other non-potable purpose. Recycling of sewage treated water directly reduce consumption of fresh water and help to come out from water scarcity problem.

Sewage treatment is the process of removing contaminants from domestic wastewater called “Sewage” coming from various part of city and inhabitant area, which includes physical, chemical and biological processes to produce an environmentally safe fluid waste stream (or treated effluent) and a solid waste (or treated sludge) suitable for disposal or reuse (usually as farm fertilizer).

Various technologies from Oxidation pond to Activated sludge process and advance MBBR to MBR process has been adopted by municipal and government bodies to provide effective treatment of domestic sewage water depending upon the uses of treated sewage water which formulate as